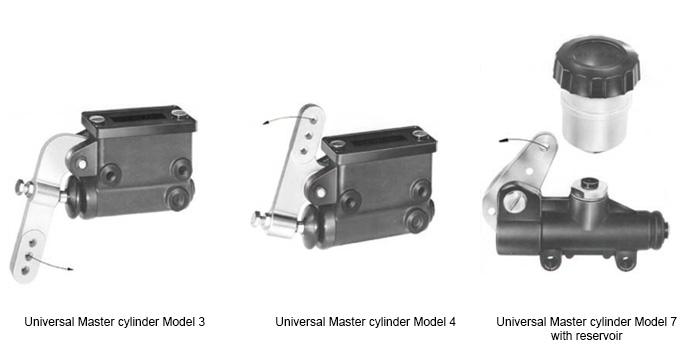

Universal Master cylinder Models 3, 4 and 7

Our universal master cylinders are suitable for many different installation situations.

Due to the integrated actuation lever a remarkable enhancement of the actuation force is realized, whereby very high braking pressures can be generated.

The solid design together with high quality sealings ensure long service intervals.

| P/N | Description | Hydraulic Fluid | Application (suitable brake assembly) |

Max. operating press. bar |

Connecting thread |

Weight g |

Remarks |

| 058230 | Model 3 | DOT4 | BZT, BZT2, 30-9, 30-63A, TOG | 100 | M10x1 | 400 | |

| 058240 | Model 4 | DOT4 | BZT, BZT2, 30-9, 30-63A, TOG | 100 | M10x1 | 400 | |

| 058270 | Model 7 | DOT4 | BZT, BZT2, 30-9, 30-63A, TOG | 100 | M10x1 | 360 | Separate mounting of reservoir possible |

| 058279 | Model 7 | Mineral Fluid | BZT, BZT2, 30-9, 30-63A | 100 | M10x1 | 360 | Separate mounting of reservoir possible |

Spare parts

| P/N | Description | Hydraulic Fluid | Remarks |

| 058541 | Sealing kit master cylinder Model 7 | DOT4 | |

| 058543 | Sealing kit master cylinder Model 3/4 | ||

| 058544 | Sealing kit master cylinder Model 7 | Mineral Fluid | |

| 058545 | Gasket ring (cover for seals) for master cylinder type 6+7 | ||

| 058174 | Below for mastercylinder Model 3/4 | ||

| 058269 | Fluid reservoir for master cylinder Model 7 | Mineral Fluid | |

| 058271 | Fluid reservoir for master cylinder Model 7 | DOT4 | |

| 058274 | Bellow for fluid reservoir #058271 | DOT4 | |

| 058277 | Cover, dummy ring and bellow | DOT4 |

Installation guidelines for master cylinders Model 3, 4 and 7:

1. The master cylinder must be installed in the specified position, maximum deviation 5°, ascending in direction of flight.

2. The available brake lever travel must allow for the necessary piston stroke.

3. The active stroke of the master cylinder piston must not be exceeded. The brake lever travel must therefore be restricted in both directions (Be careful not to damage the piston

collars).

4. There must be play of 1 mm between piston and brake lever in release position.

5. The brake lever must be pulled back to release position by a return spring. The spring must be attached to a fixed structural element.

6. The mounting bracket for the master cylinder must not yield when the brake is activated.

Important note:

Brake fluid DOT4 is strongly hygroscopic, i.e it absorbs water. This is the reason why old brake fluid has a corrosive effect. Replace brake fluid DOT4 once a year according to manufacturer’s maintenance manual.